Dental handpieces are indispensable in oral clinical treatment. Due to the large number of patients and limited handpieces, it is impossible to provide a dedicated handpiece for each person. Frequent use, repeated high temperature and disinfection will cause abrasion on some parts inside the handpiece. Therefore, it is important to know how to repair the dental handpiece.

Common malfunctions and repairing methods of high-speed dental handpieces

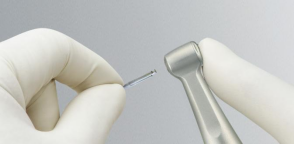

Malfunction 1: Bur cannot be clamped or removed.

Causes and its repairing methods:

(1) The diameter of the tail of the bur is small and does not meet the requirements: Standard bur needs to be replaced.

(2) Dirt plugs the slot part of chuck, preventing the chuck from closing: Clean the chuck.

(3) The three-lobed spring is worn and broken: Replace the three-lobed spring.

(4) The bur and the clamping mechanism are rusty: Replace the bur and the clamping mechanism, and give regular oil injection for cleaning and maintenance.

Malfunction 2: Handpiece does not output water/ Water yield less.

(1) Causes and its repairing methods: The water supply pressure is insufficient and the water adjustment switch is not turned on: Turn on the water switch, and adjust the normal water pressure.

(2) Waterway of the handpiece tubes are blocked: Drain the waterway of the handpiece tubes.

(3) Dirt blocks the spout of the handpiece: Clean up the dirt and keep the spout unblocked.

(4) The internal waterway of the handpiece is blocked: Drain the internal waterway.

Malfunction 3: Water leakage at the connection between the handpiece and handpiece tube or quick coupling.

Causes and its repairing methods:

(1) Connection between the handpiece and handpiece tube is not tightened: Tighten it.

(2) Four-hole or two-hole sealing gasket at the rear of the handpiece is aging, deformed and damaged: Replace the gasket.

(3) Front end of the quick coupling is deformed: If it can not be restored to its original shape, replace the quick coupling.

(4) Small O-ring at the front end of the quick coupling is severely worn: Replace the O-ring.

Malfunction 4: The phenomena of abnormal sound, loud noise, slow speed and small cutting force will occur when the handpiece works.

Causes and its repairing methods:

(1) Head of the handpiece is broken and deformed, the wind wheel has a large running resistance: Use a head repair tool to rotate and repair.

(2) The bearing lacks cleaning and lubrication: Add handpiece cleaning agent and lubricating oil.

(3) Bur is bent and deformed, and the back cover of the handpiece is loose: Replace the standard bur and tighten the back cover of the handpiece.

(4) Bearing damage: Replace the bearing. (Note: Different bearings have different installing tools. Do not install wildly. Bearing has a direction, the dust cover is facing outward, and the cage is close to the wind wheel.)

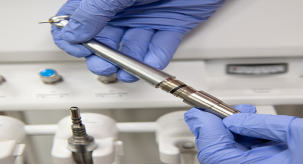

Common malfunctions and repairing methods of low-speed dental handpieces

Low-speed dental handpiece includes low-speed straight handpiece, low-speed contra-angle handpiece and motor (pneumatic or electric). Since low-speed handpiece has many parts and complex structures, we should be careful in repairing.

Malfunction 1: Motor does not rotate.

Causes and its repairing methods:

(1) Insufficient driving air pressure: Adjust the air pressure to a normal level, generally 0.25~0.30 MPa.

(2) The motor reversing ring (F forward rotation, R reverse rotation) is in the middle “O” position: Turn the reversing ring to the maximum position to the required steering.

(3) Insufficient lubrication, causing the dirt to jam the rotor: Remove the pressure ring at the front of the motor, take out the front bearing seat and rotor assembly, and clean it. After cleaning, add lubricating oil. There are tiny springs in the rotor assembly, so it should be careful not to lose them.

Malfunction 2: Straight handpiece does not rotate when it is connected with the motor.

Causes and its repairing methods:

(1) After the straight handpiece clamps the bur, the sleeve is not screwed in place: Tighten the sleeve to ensure that the bur is firmly clamped.

(2) Foreign matter in straight handpiece: Spray the foreign matter with the handpiece cleaning agent.

(3) Insufficient cleaning and lubrication lead to internal parts rust: Use specialized tools to disassemble the straight handpiece and replace the rusty parts (shaft clamps, steel balls, bearings, middle drive shafts, etc.).

Malfunction 3: When the contra-angle handpiece is running, it slips, and the bur swings violently or does not rotate.

Causes and its repairing methods:

(1) The transmission gear is worn and damaged: Disassemble the head and neck of the contra-angle handpiece, take out the upper actuator and the middle transmission, and replace the damaged parts.

(2) Damaged head cartridge: Replace the head cartridge.